Patience was rewarded when the MAI hosted the European Network for Inspection and Qualification (ENIQ) spring meeting from March 21-23: Initially scheduled for spring 2020 and postponed several times during the pandemic, the meeting gathered 34 participants, with another 6 participating on-line.

💡 ENIQ is a utility driven network dealing with the reliability and effectiveness of non-destructive testing for nuclear power plants and is recognised as one of the main contributors to today’s global qualification codes and guidelines for in-service inspection. Since its inception in 1992, ENIQ has published nearly 50 documents, including the “European Methodology for Qualification of Non-Destructive Testing”, the first qualification methodology based on technical justifications, the “European Framework Document for Risk-Informed In-Service Inspection (RI-ISI)”, and various recommended practices.

🌎 Despite the name suggesting a European initiative, ENIQ members include participants from Asia and North America as well. The meeting was also an opportunity for several side meetings, in particular between EPRI and EDF DI and EDF R&D. Participants unanimously appreciated the MAI’s hospitability and facilities, fostering lively exchanges and constructive discussions.

Contact: Andreas Schumm

The MAI is also a training centre !

🌍 We had the pleasure to welcome international students from the MaNuEn master last week at the MAI. This master is a 2-year programme for students wishing to work in the nuclear industry, in R&D or for research organisations. MaNuEn covers the specificities of materials used in nuclear environment with a particular focus on their durability under irradiation.

💡 This was a great opportunity for them to meet EDF R&D teams who are at the forefront of the research on nuclear materials ageing processes and who work daily to ensure that our nuclear power plants operate in a safe way on a longer term !

👏 Congratulations to the students for their dynamism throughout the week and many thanks to the EDF R&D researchers for their availabilities and the quality of the courses given.

Nyhal MEGHIREF, PhD, Yannick Nziakou, PhD, Jean-Christophe Le Roux, Romain VERLET, Claire Rainasse, Julien Sanahuja, Rémy Bonzom, Aurore PARROT, Adèle Astorg, Martin Bachet, Yang SHEN, Alexis GRAUX, Andreas Schumm, Pierre-Emile Lhuillier, Chaveli BITSINDOU & Jean-Pierre Hutin.

Matteo Canducci, Emanuele Diana, Alessandro Regionesi, Vuk Manojlović, Fehim Fatih Kup, Eloi Pallares Abril, Ria Meston, Lautaro Lopez Perezlindo, Daniel Francisco Zarate Parra, Mathieu Robin, Stanislas Raguin, Xavier ojeda

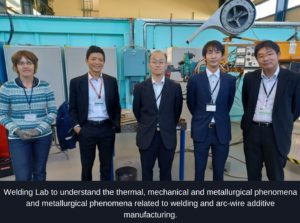

Following Fontevraud 10 conference, Kansai/INSS and MHI visited the MAI at EDF Lab les Renardières. It was a good opportunity to have face-to-face meetings with EDF experts on 2 ongoing MAI projects Kansai/INSS and MHI are contributing in :

- VIP2 : Vessel Internals project

- CSI2 : Stress Corrosion Cracking

A lab tour was also organized to visit Welding lab, Stress Corrosion Lab and Mechanical Lab.

Many thanks to Kansai/INSS and MHI for making the trip and allow us to have very fruitful discussions that would have been impossible in virtual format.

[#SherlockProjectEDF] Advisory Board of Sherlock project at Cruas nuclear power plant, France.

The objective of Sherlock project is to get a full assessment of a retired Steam Generator (SG) from Cruas 4 plant after 30 years of operation. The Advisory Board took place on 28th June on Cruas site and offered to partners (EDF, #EPRI and #FRA) the opportunity to visit the storage building and see the retired Steam Generator inside. It was impressive to get close to a retired steam generator and imagine in this building all the coming operations to cut and extract all the specimens to be sent to EDF hot Lab (LIDEC).

Shortly, Sherlock project will provide unique destructive examinations on a retired Steam Generator and will improve the asset management of current SGs as well as replaced or future SGs.

‘Quantitative STEM-EDX Analysis of intergranular Segregation Applied to the Study of Reversible Temper Embrittlement of Bainitic and Martensitic Low Alloy’

Phosphorus intergranular segregation in low alloy steels is known to decrease brittle fracture stress and induce intergranular fracture, which causes reversible temper embrittlement. In the nuclear industry, nominally bainitic steels are subjected to this phenomenon and the question of microstructure susceptibility has been raised as literature shows that martensite is more susceptible than bainite. The objective of this study is to understand if this result is related to a different segregation behavior of the two microstructures. The first part of our work establishes a segregation quantification method using STEM-EDX, that was cross-compared with four other analytical techniques. Then, a comparative study of intergranular segregation in bainitic and martensitic 16MND5 steel after different aging treatments is conducted based on the developed analytical method. The results show small microstructural influence on segregation. Phosphorus, nickel, manganese and molybdenum were observed at all types of grain boundaries in both microstructures. The segregation concentrations are higher in prior austenitic grain boundaries than in other types of boundaries. Taking account of the segregation amount in different types of boundaries, the phosphorus bulk depletion is shown negligible.

Finally, using Charpy tests, we confirm the lower susceptibility of bainite to temper embrittlement and conclude that this is not related to a different segregation behavior from martensite.

‘Effect of the presence of oxide inclusions on the prediction of stress corrosion cracking initiation of alloy 600 in PWR environment’

Nickel base alloy 600 contains 16 wt% chromium. It is susceptible to Stress Corrosion Cracking (SCC) when exposed to primary water environment. A predictive model of SCC (the ‘local’ model) has been developed in the past. It describes the phenomenology of cracking through an incubation stage (oxidation of grain boundaries), initiation (oxidized grain boundary failure) and then crack propagation. It is based on several parameters related to the environmental (temperature, dissolved hydrogen content), the microstructure (intergranular chromium carbides) and the mechanical state (work hardening, stress). However, the variables specific to industrial surface conditions such as the presence of oxide inclusions are not considered. This work focuses on the evolution of this model by studying the oxidation and SCC behaviors of models A600 that contain oxide inclusions of type Al2O3, MgAl2O4 and MgO and exposed to simulated primary water environment. Thus, characterizations of the initial microstructure were performed. Then, the oxidation behavior of these materials was established with a particular focus on the oxide inclusions. Grain boundary oxidation kinetics as well as oxide inclusion corrosion kinetics were identified. Finally, SCC tests have been performed on U-Bend type specimens and a SCC cracking criterion for grain boundaries that intercept oxide inclusions has been discussed.

On March 15, at the MAI (Material Aging Institute), representatives of 17 major players in France in the field of powder metallurgy in general and additive manufacturing in particular, met to share their experiences on the fracture toughness of alloys manufactured by these new processes. In total, more than 60 academics, researchers and industrialists were able to participate and contribute to this event.

Powder metallurgy in general or additive manufacturing in particular is a rapidly growing field with more and more applications emerging in different industrial sectors. These processes using metal powders have many advantages such as reducing the number of steps and the lead time, optimizing the design and improving the performance of parts. The alloys produced by this technology have excellent mechanical (static) properties that can exceed those of conventionally produced materials. However, the integration of these new processes in the manufacture of safety critical parts faces a major obstacle: the fracture properties of the materials thus obtained, especially in terms of impact strength, are not widely available in the literature and when they are available in some publications, they appear much weaker than those of conventional materials.

During this workshop, the partners shared work done on important industrial alloys (304L, 316L, 17-4PH, Inconel 625…). The three main families of processes were discussed in detail: hot sintering with CIC (Hot Isostatic Compression) and MBJ (Metal Binder Jetting), laser fusion with LPBF (Laser Powder Bed Fusion) and DED (Direct Energy Deposition) and cold deformation with Cold-Spray (ultrasonic spraying of cold powders).

Thank you for the numerous presentations, the diversity and richness of information and visions. We can note the presence of academic laboratories (Mines Paris Tech, Mines Saint Etienne, ENSTA, ENSAM, INP Grenoble, University of Lille, UTBM…) of industrial technical centers (CETIM, CEA, ONERA) and industrial manufacturers and end-users (Volum-E, Framatome, EDF).

During the workshop, several partners expressed their interest in participating in a collaborative project with EDF. The objective is to identify ways to improve the resistance to breakage of these materials. The industrial challenge is to specify and qualify these materials for critical applications in industry.

Bacteria to repair concrete

Speaker : Nhu-Cuong TRAN – Laurent PETIT

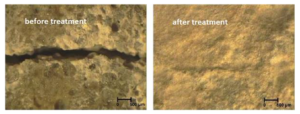

Certain bacteria (non-pathogenic) can induce calcium carbonate precipitation when put in an environment favorable to grow them in. This faculty is already used for the restoration and repair of old limestone monuments. It is also successfully tested for soil stabilization in hydraulic structures. Applied to a concrete, this technique leads to deposits of calcium carbonate that completely or partially fill in the porosity and microcracks present on the surface of the concrete (see figure above).

The implementation of this technique is on the principle quite simple; it consists in applying to the surface of the concrete an aqueous solution containing the bacterial culture (non-pathogenic) and the nutritive elements necessary for the development of its activity. The challenge is to adapt this process to concrete whose environmental conditions are not always favorable to the growth of bacteria (pH, relative humidity, temperature). In addition, to be effective and durable, it is necessary to promote treatment in the depth of the concrete.

The implementation of an injection process as well as a work on the bacterial culture with a view to improving the elastic and adhesion properties of the composite calcium carbonate / biofilm, was studied within the framework of the PhD work of Adrien Perrin. This work is carried out in collaboration with the University of Sherbrooke and the Mines Télécom Nord Europe institute. The objective is to assess to what extent this type of technique can be used for the repair of concrete structures in the nuclear industry in addition to or as a replacement for conventional techniques (epoxy resins). After a few reminders on this technique, the main results acquired during this PhD-thesis work will be presented.

The innovation brought by this project is the fact that healing products are natural products. It is anticipated that durability will be better than in other conventional repairments and will have a smaller ecological footprint. Associated costs will be thus smaller.

Replay and presentation are available for MAI and MAI-SN members.

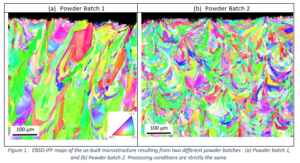

MAI-SN presentation on “Grain refinement and texture randomization in austenitic stainless steels produced by L-PBF (laser powder bed fusion)”

Inside Material Aging Institute – Scientific Network (MAI-SN), the MAI collaborates with leading universities around the world, offering two to three doctoral research programs each year to conduct PhD work on topics related to the aging of materials.

On Monday February7th, MAI-SN organized a PhD work presentation funded by MAI-SN on «Grain refinement and texture randomization in austenitic stainless steels produced by L-PBF » by Leo Monier, Phd Student under the supervision of Arthur Despres, Guilhem Martin, Jean-jacques Blandin and Muriel Veron in the SIMAP Laboratory, Grenoble and under the supervision of Flore Villaret, Yang Shen and Bernard Yrieix at EDF R&D for MAI-SN.

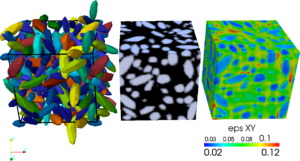

Additive manufacturing is an opportunity for the energy field to produce sophisticated geometries. However, there are still several roadblocks to its use to make a wide variety of parts. One needs to demonstrate that parts produced with conventional processing routes can be substituted by parts fabricated by additive manufacturing. The objective of this work is to shed light on the microstructure-mechanical property relationships of the 316L austenitic stainless steel produced by laser powder bed fusion (L-PBF). Parts made of 316L stainless steels have been fabricated using two different powder batches while keeping the exact same processing conditions. The two powder batches led to very different microstructures. The nominal composition of the two initial powder batches differs slightly. Based on a multi-scale microstructural characterization from the melt pool scale down to the nano-scale, we highlight substantial differences between the two investigated steels. Powder batch 2 leads to a finer grain structure that goes along with texture randomization. The underlying mechanism responsible for grain refinement and texture randomization is discussed and can be considered as an alloy design strategy in the framework of additive manufacturing.

The purpose of the MAI-SN is to create a strong and permanent link between academic researchers and utilities members of MAI.

This master degree is an international 2 years master program for students willing to work in nuclear industry, R&D or research centers. It is designed to train students with basic nuclear engineering knowledge , and fundamental understanding of materials behavior under irradiation i) to predict the aging of nuclear power plants and ii) to meet materials challenges for the future.

Students have a privileged contact with engineers working in the nuclear industry (EDF, CEA) in an international network providing good job opportunities.

MAI has been welcoming the winter training session for many years. Due to covid situation, the course was held online for the second time.

The MAI 2022 session welcomed 7 master students from 5 different countries (Italy, USA, Colombia, Indonesia, Greece). Every year, a lab tour is planned for students to understand how important experimental facilities are in the field of Materials Aging. This year, students could enjoy virtual lab visits with live presentation and interaction.

MAI-SN presentation on “ Experimental evaluation of EDF’s InterGranular Stress Corrosion Cracking (IGSCC) predictive models ”

———————————————-

Inside Material Aging Institute – Scientific Network (MAI-SN), the MAI collaborates with leading universities around the world, offering two to three doctoral research programs each year to conduct PhD work on topics related to the aging of materials.

On November 24th, MAI-SN organized a PhD work presentation funded by MAI-SN with a presentation on « Experimental evaluation of EDF’s InterGranular Stress Corrosion Cracking (IGSCC) predictive models » by Naganand Saravanan (PhD Student, Oxford University).

Primary Water Stress Corrosion Cracking (PWSCC) is a major problem faced by operators of Nuclear Power Plants for decades. The development of predictive tools to anticipate SCC occurrences is a crucial challenge. New engineering models have to quantitatively predict the evolution of SCC (path and depth vs. time) in 3D industrial components, in order to help end-users to manage the risk of failures.

The Local Model developed by EDF has the ability to predict IGSCC initiation in a phenomenological approach combining experimental and simulation data to overcome the limitations of the empirical Index Model. Local model relies primarily on a cracking scenario and local parameters, defined at grain boundaries.

The purpose of this PhD work is to ensure that the underlying assumptions of the Local Model about SCC mechanisms are realistic enough to make sure the model is reliable for application to reactor components. To this end, experimental and modelling programs were conducted on Alloy 600, a nickel-based alloy widely used in Pressurized Water Reactors, with the following three main objectives:

- Provide a fully comprehensive experimental dataset suitable for the evaluation of EDF’s IGSCC models

- Identify the strengths and limitations of the model predictions thanks to the comparison with the experimental datasets

- Propose improvements of the EDF’s IGSCC predictive model

| 1 |  |

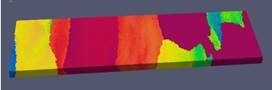

3D polycrystalline aggregate reconstructed from 3D EBSD dataset

(16 grains, 185x60x18 µm) |

|

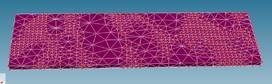

| 2 |  |

|

3D finite element mesh and orientations |

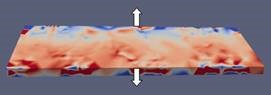

| 3 |  |

CPFEM calculated Principal Stresses for 2.5% applied strain | |

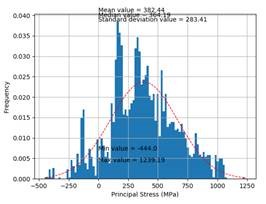

| 4 |  |

Histogram of the Principal stresses used to estimate the critical stress to fail oxidized grain boundaries (input data of the EDF Local Model) | |

Figure : 3D equivalent polycrystalline aggregates have been generated from the microstructural data and Crystal Plasticity Finite Element Modeling (CPFEM) local stress evaluations have been done.

The purpose of the MAI-SN is to create a strong and permanent link between academic researchers and utilities members of MAI.

The Materials Aging Institute and RosenErgoAtom offer Materials Degradation Course for Engineers in The Nuclear Industry. We are proud to bring you the best international experts of nuclear industry on material aging issues.

The aim of this course is to start from the fundamentals and provide an integrated and up-to-date picture of materials management in the current LWR fleet with a special emphasis on PWR and VVER Field experience. Degradation management approaches will be described and linked to our current understanding of degradation mechanisms of carbon and low alloy steels, stainless steels, nickel based alloys, concrete and polymers under LWR service conditions.

It will be 100% digital on November 29th to December 3rd 2021.

If you are interested, register here : https://lnkd.in/gS74vnTs

For more information you will find the attached flyer with the agenda.

The aim of this workshop is to provide an international forum for reporting progress and recent advances in micromechanics and its applications to cementitious materials.

Topics include, but are not restricted to: multiscale methods and tools, advanced experimental techniques to provide input or validation data, microstructure investigation and modeling, non destructive testing, delayed strains, swelling phenomena, strength, damage, degradation mechanisms, transport properties.

Contributions are warmly welcomed.

Abstracts should be submitted by e-mail to the technical contacts provided below.

- Date and location:

Wednesday 29 september 2021, whole day, Teams remote meeting.

- Practical aspects:

– Official announcement on MAI website:

https://www.themai.org/workshops/

– Free but mandatory registration:

- For more details, please contact:

– Administrative information: Liloo Moutot (liloo.moutot@edf.fr),

– Technical information: Julien Sanahuja (julien.sanahuja@edf.fr).

Concrete and cementitious materials properties and behaviors are of paramount importance to manage long term operation of civil engineering structures. Relevant material properties and behaviors are required to perform structural finite element computations and to interpret most non destructive techniques. As concrete mixes are very diverse, properties from one concrete may not be suitable for another one.

Micromechanics and, broadly speaking, homogenization techniques, allow to investigate composite materials behaviors and properties from their microstructure and micromechanisms. They form a toolbox of choice to build physics-informed models relating properties to mix design, or cross-relating several properties (for non destructive techniques based on indirect measurements, eg: measure permittivity to assess water content).

This short online course (1H30) proposes an introduction to basic principles of micromechanics and some applications to civil engineering.

Objectives :

– Get an overview of concrete civil engineering questions at EDF R&D that have been investigated through micromechanics,

– Get familiar with basic principles of micromechanics,

– Experience a demonstration of a software toolbox dedicated to estimating concrete properties and behavior.

Audience :

– Engineers and researchers in the field of civil engineering, with backgrounds in continuum mechanics and mechanics of materials.

This training is free and will be performed on line.

If you are interested on this training :

- Date: Monday 20 september 2021

- Time: 13h00 – 15h00 CEST

- Free but mandatory registration:

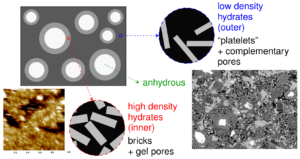

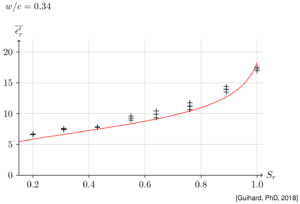

Morpho paste : One important starting point of micromechanical models is microstructure representation. The figure shows a 3D morphological simplification of the cement paste microstructure.

Permit paste : A classical non destructive technique to assess water content is permittivity measurement. However, this indirect approach requires a “calibration curve” relating dielectric permittivity to water content, this curve depending on the concrete at stake. The experimental process is heavily time-consuming, mainly due to the very slow drying processes. A model based on homogenization has been recently developed: it is parametrized by the mix design. The plot shows a comparison to experimental measurements on a cement paste.

Inside Material Aging Institute – Scientific Network (MAI-SN), the MAI collaborates with leading universities around the world, offering two to three doctoral research programs each year to conduct PhD work on topics related to the aging of materials.

On Friday 3rd september, MAI-SN organized a PhD work presentation funded by MAI-SN with a presentation on Understanding the Role of Hydrogen in Stress Corrosion Cracking in Austenitic Alloys by Florence CARRETTE (EDF R&D) and Edwards Roberts (PhD Student from Oxford University).

Austenitic alloys are commonly used in the nuclear industry due to their high corrosion resistance and excellent mechanical properties. However, it is possible for critical structural components made from these alloys to undergo stress corrosion cracking (SCC) under pressurised water reactors (PWR) conditions. As the primary method of material degradation, SCC has been studied extensively for several decades, and many factors have been shown to affect SCC susceptibility, these include cold-work, temperature, and water chemistry. To develop a better mechanistic understand of SCC, further research is required. The main objective of this project is to correlate the SCC crack growth rate’s (CGR) dependency on nickel content, first observed by Coriou and later by Arioka, with both the localised mechanical deformation and hydrogen up-take at PWR temperatures. To meet these aims, three alloys have been systematically tested in every chapter. These include SS316L (12%-Ni), A800 (32%-Ni) and A600 (72%-Ni) as they represent commercially available alloys with a low, intermediate and high nickel contents.

The purpose of the MAI-SN is to create a strong and permanent link between academic researchers and utilities members of MAI.

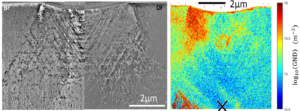

Figure 1: (left) Fore-scattered diode images of a cross-section of a nanoindent in cold-worked SS316L with no corrosion. (right) Geometrically necessary dislocations generated during nanoindentation, calculated by correlative techniques from transmission Kikuchi Diffraction data.

The purpose of the MAI-SN is to create a strong and permanent link between academic and industrial world.

MAI-SN is proud to offer a scientific day on « Aging Modelling to optimize plant operation ».

Material aging in power plant can hinder the course of operations. Precise physically-based modelling can help to lighten these constraints and to mitigate aging.

During the scientific day, 3 plenary sessions will present latest development in modelling aging processes in metallic alloys, concrete structure and polymers aging. A poster session will also present recent PhD works. Enjoy as well a tour of unique industrial facility on material aging. Remote connection will be available for those who cannot attend in-person. Language : English.

It will be the place where industrials and academic researchers can exchange their experience in this field.

For more information, see the flyer attached

If interested, click on the link to register

https://lnkd.in/gRf8Rrx

Inside Material Aging Institute – Scientific Network (MAI-SN), the MAI collaborates with leading universities around the world, offering two to three doctoral research programs each year to conduct PhD work on topics related to the aging of materials.

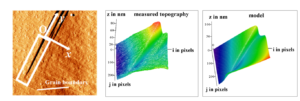

On Friday 25th June, MAI-SN organized a PhD work presentations funded by MAI-SN with a presentation on Characterization of slip bands and their interaction with grain boundaries by Prof. Charlie KAHLOUN, Dr. Giath MONNET (EDF R&D) and Aida MAJOUL (PhD Student).

Components of Pressurized Water Reactors (PWR) are submitted to various in-service loading, neutron flux, thermal fluctuations and aggressive environment, leading to different types of embrittlement, such as thermal fatigue (embrittlement of cooling circuit), Irradiation Assisted Stress Corrosion Cracking (IASCC of baffle bolts), thermal shock (cleavage of RPV steels), etc. Fracture assessment is required to meet the imposed safety margins. In all fracture models, stress concentrations play the key role in crack nucleation and/or propagation. One of the most known and well-identified stress concentration sources is the interaction of slip bands with Grain Boundaries (GBs). This interaction is strongly enhanced during the formation of clear bands (case of irradiated austenitic stainless steels).

This PhD is dedicated to the characterization of slip bands and their interactions with GBs. Once achieved, we expect the results of this work to: (i) provide a valuable set of data for validation of fracture models; (ii) improve predictions of crack nucleation/propagation by accounting for strain localization, so far ignored in the classical framework of crystal plasticity employed in R&D studies.

The purpose of the MAI-SN is to create a strong and permanent link between academic researchers and utilities members of MAI.

Figure 1 : (a) example of topography obtained from the AFM signal, (b) the measured topography in pixels and (c) the fitted topography that can be derived to obtain the GND density tensor

Material aging in power plant can hinder the course of operations.

Precise physically-based modelling can help to lighten these constraints and to mitigate aging.

During this scientific day, we will review how this can be done.

3 sessions related to metals, polymers and concrete will bring out a general overview of the latest developments while a keynote lecture will synthetize the past and recent successes.

It will be the place where industrials and academic researchers can exchange their experience in this field.

If interested, please contact Chaveli.Bitsindou@edf.fr

CIENPI (China International Exhibition on Nuclear Power Industry) is the largest Chinese nuclear industry exhibition. From 14th to 16th April, MAI was present at this exhibition.

3 MAI projects were put forward : vessel internals (VIP), polymer aging (POLYAGE) and civil engineering (CISTERN). As digitalization was the main topic of this exhibition, there were many very interesting exchanges on Vessel Internals results and digital twin in CISTERN project (Vercors Mockup).

Inside Material Aging Institute – Scientific Network (MAI-SN), the MAI collaborates with leading universities around the world, offering two to three doctoral research programs each year to conduct PhD work on topics related to the aging of materials.

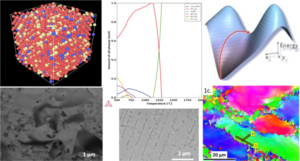

Last Monday april 12th, MAI-SN opened a cycle of PhD work presentations funded by MAI-SN with a presentation on High Entropy Alloy (HEA) by Pr. Anna FRACZKIEWICZ (Mines de Saint-Etienne) and Dr. Gilles ADJANOR (EDF/R&D).

High-entropy alloys (HEA) are concentrated alloys having a particularly stable solid solution compared to usual alloys. Some of them started to receive considerable community interest when several studies pointed out an outstanding combination of mechanical properties allowing both high yield strength and fracture toughness, especially at low (cryogenic) temperatures.

The purpose of the MAI-SN is to create a strong and permanent link between academic researchers and utilities members of MAI. This presentation provided an overview of the potential benefits of HEA for nuclear utilities.

Below is an explanation of the photo :

From left to right and up to down: snapshot of atomic positions in a molecular dynamics simulation of an FeNiCr high entropy alloy (HEA) ; phase stability as predicted by ThermoCalc ; schematic of the saddle point for an atomic diffusion jump as identified by the k-ART code in a free energy landscape ; nanostructure from transmission electron microscopy in an austenitic HEA ; and its structure after thermal aging ; partial recrystallization of an HEA observed by electron backscatter diffusion

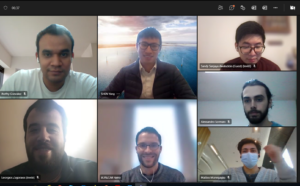

On 21 January 2021, EDF, Tianjin University and CNNC held a meeting to launch a tripartite PhD work on ” STUDY ON COUPLING MECHANISM OF FRETTING WEAR AND CORROSION OF HEAT EXCHANGER TUBE UNDER OPERATING ENVIRONMENT “, which will last three years.

Inside Material Aging Institute – Scientific Network (MAI-SN), EDF collaborates with leading universities around the world, offering two to three doctoral research programs each year, with leading institutions to conduct research on topics related to the aging of materials. This is the first time that EDF is cooperating with the University of Tianjin.

Due to the epidemic, this meeting was held using a combination of online and offline methods.

Guorui Zhu presented the progress of the group’s research and the basis for the preliminary work on this project. Antoine AMBARD presented the requirements of the MAI-SN project, XU Tingting presented the research plan of this project, and Shengzan Zhang, the PhD student, presented the research method and the implementation plan of the project.

The success of this meeting laid a good foundation for tripartite cooperation to progress on understanding and mitigating wear issues.

![]()

![]()

25th to 29th January 2021

This master degree is an international 2 years master program for students willing to work in nuclear industry, R&D or research centers. It is designed to train students with basic nuclear engineering knowledge , and fundamental understanding of materials behavior under irradiation i) to predict the aging of nuclear power plants and ii) to meet materials challenges for the future.

Students have a privileged contact with engineers working in the nuclear industry (EDF, CEA and Framatome) in an international network providing good job opportunities.

MAI has been welcoming the winter training session for many years. Due to covid situation, the course was held online.

The MAI 2021 session welcomed 11 master students from 9 different countries (Argentina, Spain, Italy, Jordan, Azerbadjian, Nigeria, Costa Rica, USA). More than 20 instructors from EDF presented EDF facilities and gave lectures on Non-Destructive Testing and Inspections, civil concrete, polymers, chemistry, corrosion and radiolysis, nuclear fuels, mechanical and thermal fatigue and maintenance of NPPs. Some of the instructors used game-based learning platforms to improve the interactivity with students and to make a more lively presentation of EDF facilities.

Discover the Handbook of material ageing management for nuclear reactors

Discover the Handbook of material ageing management for nuclear reactors