Each year MAI SN funds fundamental works on aging, typically PhD. Usually, MAI SN founds about two Ph.D. a year. Co-funding with other institutions, especially MAI members is warmly welcome and would be favoured in the ranking.

-

All Proposal should be sent to antoine.ambard@edf.fr, marie.berthelot@edf.fr

-

All proposals should be received before (dates in texts below)

-

Proposal should indicate :

– Funding requested – MAI will favour co-funded proposal.

– Description of the scientific work and how it answers the specific problems described in the text of the call

– Short presentation of the people involved in the proposal

Open calls

Closed calls

1 Object

The production by additive manufacturing of powder bed selective laser melting (SLM) and arc-wire (WAAM) of parts made of austenitic alloys (stainless steels and nickel base alloys) presents difficulties in terms of processes, effective properties and their qualification, which are described hereafter.

Indeed, it is found that the final mechanical properties are on the one hand different from traditional counterparts and on the other hand anisotropic. The amplitude of these differences and this anisotropy can be considerable, thus calling into question the fitness for use as well as the design of the part itself based on codes which do not manage these particularities (e.g. RCC-M).

The origin of these properties is the particular and textured microstructure obtained on part, itself inherited from the specificities of the processes. Mastering the entire chain from the process, the finishing touches, to the qualification or even the codification of such parts, requires causal links between the process parameters, the microstructure and the mechanical properties (including the mechanical constitutive laws and material fracture while considering anisotropy). As final users MAI members need this mastering to secure the fitness for use.

So, MAI SN wishes to provide the corresponding knowledge. The following paragraphs summarize the microstructural particularities and that affecting the mechanical properties. Finally the scientific challenge that this call calls has to solve is explained.

2 Specificity of these products

The specifics compared to traditional manufacturing are described briefly, with a few reference which do not constitute an exhaustive state of the art but just a desire to illustrate the point.

2.1 Processes

The SLM process implements solidification under conditions of extreme temperature gradients and speed of solidification, which are common to laser welding. Successive juxtaposed refusals also lead to severe work hardening in a wide temperature range.

The WAAM process differs from the corresponding welding by the search for high deposition rates and a difficulty in controlling thermal conditions due to the high arc time.

2.2 Materials

The problem mainly affects austenitics (steels and nickel base) and aluminium alloys, that is to say alloys that do not exhibit massive solid phase transformation during cooling. The transformation during continuous cooling of austenite allows low and high alloy steels to regenerate the structure either directly or during reaffectation and thus erase much of the previous metallurgical history.

This is obviously not the case with austenitics widely used in our installations and which therefore constitute a particularly complex case requiring the studies mentioned. For practical reasons and industrial interest the material selected to study this issue is 316L (Z 2 CND 17-12) steel, without excluding some work on nickel alloys which will have similar behaviours.

2.3 Microstructure

The differentiating microstructural parameters are as follows. Some are close to welding microstructures.

Grain orientation. Very dependent on the deposition conditions, more or less marked orientations of the grains are possible. Most often they are in the cross direction therefore the opposite of the wrought.

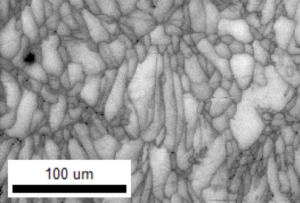

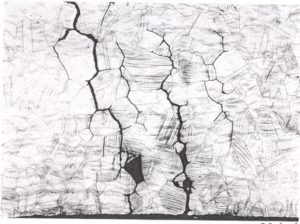

Grain size. SLM can lead to particularly fine grains (Figure 1), while WAAM tends to produce very large grains like multipass welding.

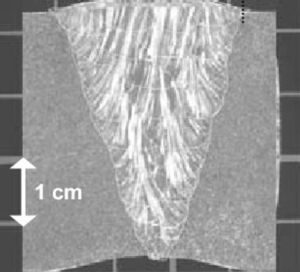

Figure 1: Very fine grains from 316L SLM Figure 2: multipass welding of austenitic

© G. Sattonnay, 2018 stainless steel © Le Marrec 2011

Crystal texture. Solidification in a strong temperature gradient leads to a marked crystalline texture but which can be modified to a large extent by the lasing or deposition strategy (example Figure 3).

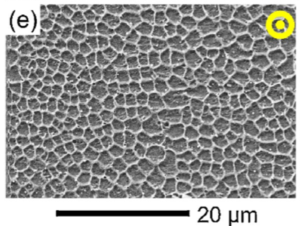

Solidification cell. The solidification speed / thermal gradient couple panel leads to different types of solidification: plane, cellular or columnar dendritic with the induced sub-structures such as solidification cells (example Figure 4).

Figure 3 Example of crystal texture on a 316 SLM |

Figure 4 Example of solidification cells |

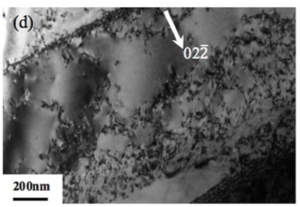

Density of dislocations. The intense and repeated thermo mechanical stresses lead to strong (WAAM) to very strong (SLM) densities of dislocations.

Dislocation cells. The work hardening is sudden at variable and cyclic temperatures which can cause a dynamic restoration and lead to quite marked dislocation cells (example Figure 5). Note: the question of recrystallization is not very clear.

Figure 5 Dislocation cells observed in a 316L SLM |

In conclusion, the microstructure is very multi-scale without it being always possible to do without one of these scales in its description.

2.4 Mechanical properties

In the as build state, that is to say before any heat treatment, it is found differences in properties compared to the traditional material and a strong to very strong anisotropy (some examples for SLM are given Table 1).

Table 1 – Some static mechanical properties of 316L SLM

| Reference | Machine | Ys (MPa) | Us (MPa) | A% | Kv (J) | ||||

| Direction/built | ^ | // | ^ | // | ^ | // | ^ | // | |

| RCCM 3306/7

Direction/wrought |

≥ 175 | ≥ 490 | ≥ 40 (T) ou 45 (L) |

≥ 100 | |||||

| Typical values./ Amb. | 210 / 240 | 480 / 530 – 700 | 50 / 40 | ||||||

| Erikson 2018 As build | 1 | 615 | 525 | 725 | 625 | 35±15 | 48±10 | 124 | 144 |

| 2 | 530 | 455 | 655 | 585 | 31±2 | 20±6 | 28 | 20 | |

| Kurzynowski 2018 As build / HT 800 °C 5 h |

3 | 515 | 685 | 32 | |||||

| 463 | 685 | 25 | |||||||

| CEA, brut | 5 | 580 | 515 | 700 | 615 | 40 | 48 | 78-104 | 98-113 |

| Hitzler 2017 | 6 | 510 | 635 | 440 | 515 | 12 | 33 | ||

In general, but in variable proportion, the elastic limit, the tensile strength and the hardness are higher while the elongation at break, the impact toughness and the Young’s modulus are lower. The origin for the former is attributed to both the work hardening and the “synergy” between the different scales (a kind of Hall-Petch effect). The latter might be attributed to texture effect but it remains to be investigated and demonstrated.

The atypical side of microstructures and static mechanical properties also raises the question of dynamic properties (fatigue, creep), and failure beyond the potential low values of impact toughness. Indeed, the modes of damage on the one hand and the developing of the plastic zones on the other hand are likely to be modified compared to conventionally manufactured 316L.

3 Scientific challenge

The non-conventional mechanical behaviour with strong anisotropy result from the microstructural specificities (crystal texture, anisotropic grains, dislocations network and solidification cells) which are in turn function of the manufacturing process.

So the responsibilities of the industrial actors are quite well defined: on the one hand the manufacturer has to provide high quality and reproducible material and parts, and on the other hand the designer and end-user like MAI members have to design their parts with realistic and optimised properties to match their specific use conditions.

As a consequence, the link between microstructure and the mechanical properties and the corresponding modelling has to be established to take fully advantage of additive manufacturing of austenitic alloys. A brief literature survey shows that it has hardly been finalized: part of the link have been established whereas a global one is lacking.

4 Call for proposal

MAI-SN intend to fund research work (typically one or two PhD) dedicated to establish:

- A metallurgical explanation of the specificities of microstructure of alloys elaborated through different additive manufacturing process like SLM and WAAM;

- The mechanical properties (elastic, plastic and anisotropy of both) of the alloy elaborated through SLM and WAAM as well as their relation with the peculiarities of the microstructure;

- Constitutive law.

The material selected to study this issue is 316L (Z 2 CND 17-12) steel, MAI SN will not consider proposals with other materials.

The ultimate objective of the work is to pave the way for introducing such SLM or WAAM manufactured alloys in design codes and industrial practice of MAI members.

- All proposals should be received before end of august

- Any question related to the proposal should be sent to bernard.yrieix@edf.fr

Each year MAI SN funds fundamental works on ageing, typically PhD. In 2020, MAI SN intends to fund works on stress corrosion cracking of materials. We plan to fund about PhD or Postdoc. Co-funding with other institutions, especially MAI members is warmly welcome and would be favoured in the ranking.

Stress corrosion cracking (SCC) is an acting degradation mechanism in nuclear power plant. MAI has long demonstrated it. Field examinations were published in [1] showing SCC of the stainless steel pipe and 718 alloy grid spring [2]. For utilities, the key question related to maintenance is the kinetics initiation and propagation of SCC. A precise knowledge of SCC kinetics would allow to plan replacement and to demonstrate safety margins. Which are especially important when dealing with the stainless steel pipe of the safety injection system.

Robust initiation or propagation kinetics presupposes an understanding of the mechanisms of SCC as well as knowledge of the stresses values which operate at the microstructural scale, in particular in the neighbourhood of grain boundaries. The stresses operate on this scale (second order stresses), can be estimated by finite elements (FE) or measured experimentally by large instruments like synchrotron. Both approaches have drawbacks. The first one requires the experimental validation of the constitutive laws of ”grains” of material. The second implies frequent access to large instruments that is incompatible with the industrial needs.

The promising technique of electron microscopy called HR EBSD is capable of such stress measurements. Moreover it can be easily implemented in a laboratory, including in a hot cell laboratory. Currently, HR-EBSD approach uses comparisons with selected reference area within each grain of the microstructure. The technique has the limitation of not allowing the determination of the “absolute” state of stress at the position of these references. This last point makes it difficult to compare with finite element calculations or absolute stress measurements made by XRD for which the measurements correspond to the local stress averages on a macroscopic scale (first order stresses).

In order to fill this gap, it is necessary to adopt new approaches such as the comparison with simulated models using the dynamical theory [3] or by analysing each of the diffracting planes in 3 dimensions using the spherical Radon transform. [4]. Reference [3] used simulations that do not take into account the excess and deficiency (ED) characteristics of EBSD models. The enrichment of the simulations of the ED effect as proposed in reference [5] should allow both an improvement in the determination of the geometry of the camera, the orientation of the crystals and the measurement of the absolute stresses. The challenge would be to keep the phantom strain effect as low as possible (usually less than 10-3) even in the presence of a highly plastically deformed crystal.

The lifting of this technological lock would present a remarkable advance for SCC study. MAI SN is interested in developments allowing the absolute measurement of second-order stresses using HR EBSD and wishes to support in-depth work dedicated to the improvement of the historical technic to extend it to an absolute measurement.

The proposal could be linked to a correlative microscopy study between HR EBSD and a near-field microscopy like Scanning Kelvin Probe (SKPFM) technic use by reference [6]. The goal is to use SKPFM maps to evaluate the effect of stresses and defect density of the crystal lattice on the heterogeneities of the metal surface potential. Of course samples corroded in primary water would be favoured.

MAI SN is ready to fund one PhD work related to this scientific problem. It is asking for proposal. Each proposal will provide a request of funding. Co-funding with other institutions, especially MAI members is warmly welcome and would be favoured in the ranking.

Questions and proposals should be asked to:

Call for proposal ends September 30th 2022.

[1] Cattant F, Materials ageing in light water reactors – handbook of destructive assays, Editions Lavoisier, Feb. 2014, 1167 p. [2] Leonard KJ, Gussev MN, Stevens JN, Busby JT. Analysis of stress corrosion cracking in alloy 718 following commercial reactor exposure. J Nucl Mater. 2015; 466:443‑59. [3] Tanaka T, Angus J. Wilkinson A J. Pattern Matching Analysis of Electron Backscatter Diffraction Patterns for Pattern Centre, Crystal Orientation and Absolute Elastic Strain Determination – accuracy and precision assessment. Ultramicroscopy DOI: 10.1016/j.ultramic.2019.04.006 [4] Nolze G, Tokarski T, Rychłowski L, Ciosc G, Winkelmann A. Crystallographic analysis of the lattice metric (CALM) from single electron backscatter diffraction or transmission Kikuchi diffraction patterns. JAC. 2021; ISSN 1600-5767 [5] Winkelman A, Nolzec G, Ciosa G, tokarskia T, Ba la P, Hourahine B, Trager-Cowan C. Kikuchi Pattern Simulations of Backscattered and Transmitted Electrons. Journal of Microscopy Nov 2021 page 157-184 [6] Madjid Sarvghad, Theodore A. Steinberg, Geoffrey Will, Scanning Kelvin Probe Force Microscopy as a means for comparative quantification of cold-rolling and visualizing the surface susceptibility to galvanic cells; compared to neutron diffraction and EBSD, Progress in Surface Science, (2020) 100594, https://doi.org/10.1016/j.progsurf.2020.100594In 2000, few cases of IGSCC have been observed in pressurizer heaters of French PWRs, in high strain hardened and non-sensitized 316L austenitic stainless steels exposed to hydrogenated primary environment. In 2012, EDF started to perform extensive preventative maintenance of the bolting in primary pumps. Several degradations have been observed on bolts and studs [[1]]. In particular, IGSCC was found on the stud of a Reactor Coolant Pump (RCP), manufactured with A286 stainless steel (containing about 15% chromium and 25% nickel). The environment was the nominal primary fluid at about 293°C. More recently IGSCC was found in the heat affected zone of 316LN pipes of the safety injection system of a plant after 20 years in-service at a temperature close to 290°C.

Fig. 1. IGSCC in CW316 SS (heater of pressurizer).

Fig. 2. IGSCC in A286 SS (primary pump stud).

As a consequence, a continuous Research program is conducted at EDF for many years in order to understand and to propose engineering models to predict SCC initiation and crack growth in cold worked (CW) stainless steels, and finally, to identify ways of improvement of existing components to prevent SCC. Therefore, many SCC tests have been achieved on a large variety of specimens (RUBs, Ubends, C-rings, round tensile, CT) under static of cyclic loading (typically one brief partial unloading per hour).

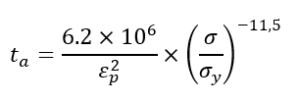

Laboratory data were first used to fit the parameters of a simple conservative model giving the time (h) to initiate a 50 µm-deep crack as a function of the total plastic strain ep level, the applied s and yield sy stresses (MPa) at high temperature (Eq. 1). It was not possible to calibrate the activation energy between 290°C and 360°C with the existing dataset. The dataset is too small to offer a good confidence in predictions but this preliminary calibration allowed to start preliminary SCC simulations.

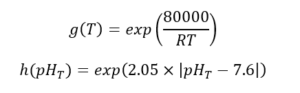

|

(Eq. 1) |

More recently, a phenomenological ‘local’ model started to be calibrated. In this model, the incubation of SCC is predicted by the intergranular oxidation kinetics, and the initiation is the probability to fail sufficiently oxidized grain boundaries. The parameters of such a model were already fitted for 316(L) and A286 stainless steels [[2]].

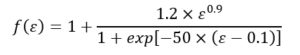

The oxidation depth p (nm) is supposed to follow a logarithmic dependency to time (h) (Eq. 2).

| (Eq. 2) | |

|

(Eq. 3) |

|

(Eq. 4) |

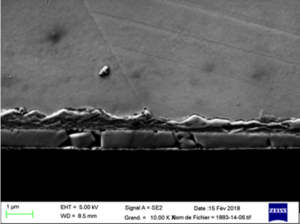

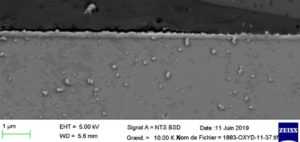

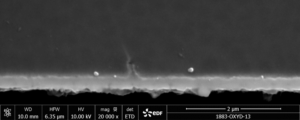

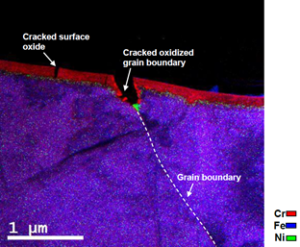

Except for and , parameters were fitted using »8000 h oxidation tests in hydrogenated and in non-deaerated primary water at 290°C and 360°C on specimens cut in CW 316 SS. For strain and pH dependencies, parameters calibrated in previous studies on other stainless steels were used [[3], [4], [5]]. Deeper oxide intrusions were noticed at 290°C (Fig. 3) than 360°C (Fig. 4), in hydrogenated water. Fig. 5 illustrates the oxidation of a grain boundary in hydrogenated water at 360°C, about two times deeper than the passive layer. In the local model, it is assumed that initiation is possible (Fig. 6) at a grain boundary as soon as the intergranular oxidation exceeds a critical depth, and the intergranular opening stress is higher than a critical value [2,3]. Recent observations suggest that the critical intergranular stress to failure decreases when the oxidation depth increases.

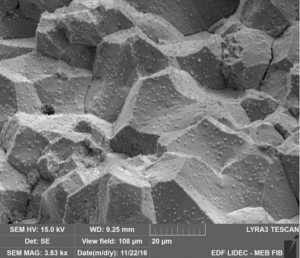

Fig. 3. Uniform oxidation observed (SEM) on CW316 after 3111 h in hydrogenated (20 ml.kg-1 H2O) primary water at 290°C.

Fig. 4. Uniform oxidation observed (SEM) on CW316 after 2689 h in hydrogenated (20 ml.kg-1 H2O) primary water at 360°C.

Fig. 5. Intergranular oxidation observed (SEM) on CW316 after 7166 h in hydrogenated (20 ml.kg-1 H2O) primary water at 360°C.

Fig. 6. Cracked grain boundaries in oxidized CW316L (T217) after after 6% el. under vacuum corresponding to 412 MPa in average in the specimen [3].

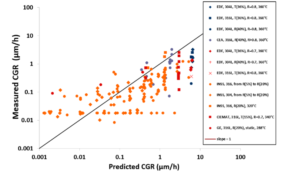

The crack growth model (Eq. 5) relies on a crack growth rate (CGR) with sigmoid dependencies to the stress intensity factor (K) and to the total plastic strain ep. The influence of temperature T is also considered, with an activation energy of 107 kJ.mol-1. Parameters were fitted using a large database including results from open litterature [[6],[7],[8],[9],[10],[11],[12],[13],[14],[15],[16]] where tests were performed in hydrogenated water under static or trapezoidal loading. Fig. 7 compares predicted to observed CGRs. Predictions are not fully conservative, especially for CGRs lower than 10-2 µm.h-1. The effect of oxygen intrusion on cGR is not considered at this level.

|

(Eq. 5) |

Fig. 7. Prediction of CGR (according to Eq. 15) vs. observation.

Finally developed models can be used to predict the location and the kinetics on components with Code_Coriolis SCC code, developed at EDF and MAI [2, [17]]. Code_Coriolis is a 3D Finite Element Modeling (FEM) post analysis, closer to the actual situation than traditional 1D or 2D approaches. Kinetics and crack growth paths are predicted. Statistics on initiation time and cracking locations are possible. FEM post analysis allows to better evaluate the relevance of SCC models and to better fit model parameters, chaining initiation with crack growth at large scales (from nanometers to centimeters).

Thus, analyses are not restricted to a single stage of the degradation and a global view of the degradation is systematically delivered. First, the methodology allows reducing/clarifying some classical assumptions (total stress, initiation depth, chaining between SCC stages…) regarding models. Second, the methodology allows to rapidly quantify factors of improvement (FOI) of components as soon as a mitigation is envisaged.

Many ways of improvement could be investigated to better predict in-service SCC:

- Heat to heat effects

- Dependency to temperature and electrochemical potential

- Dependency to loading variation (frequency, amplitude)

- …

MAI SN is ready to fund one PhD work aiming at improving the understanding of SCC of CW stainless steel (316LN is favored). Some specimens are available (detailed list available upon request) and could be made part of the research work. Explanations of how the results could be integrated to the overall validation of code-coriolis would be appreciated.

The proposal should state what is the funding requested. Co-funding with other institutions, especially MAI members is warmly welcome and would be favoured in the ranking.

Questions and proposals should be addressed to:

The call for proposal ends September 30th 2022.

Cited documents

[[1]] Y. Shen et al, ‘Degradation and optimization of Reactor Coolant Pump diffuser studs in A-286’, proceeding of the Fontevraud 9 International Conference, Avignon (France), 2018.

[[2]] T. Couvant, M. Dib, Y. Shen, C. Thaury, F. Oliveira, C. Rainasse, P. Grandclément, ‘Toward a simulation of in-service SCC observed on Reactor Coolant Pump diffuser studs – A support to failure analyses’, Fontevraud 9 International Conference, Avignon (France), 2018.

[[3]] T. Couvant, D. Haboussa, S. Meunier, G. Nicolas, E. Julan, K. Sato, F. Delabrouille, ‘A simulation of IGSCC of austenitic stainless steels exposed to primary water’, 17th International Conference on environmental degradation of materials in nuclear systems-water reactors, Ottawa (Canada), 2015.

[[4]] T. Couvant, L. Legras, A. Herbelin, G. Ilevbare, A. Musienko, G. Cailletaud, J. Hickling, ‘Development of Understanding of the Interaction Between Localized Deformation and SCC of Austenitic Stainless Steels Exposed to PWR Primary Environment’, 14th International Conference on Environmental Degradation of Materials in Nuclear Power System (Virginia Beach, Virginia, USA), 2009.

[[5]] T. Couvant, J.M. Proix, A. Seyeux, ‘Modeling intergranular stress corrosion cracking of austenitic alloys exposed to PWR primary water’, Eurocorr International Conference, Istanbul (Turkey), 2012.

[[6]] L. Tribouilloy, F. Vaillant, J.M. Olive et al., ‘Stress Corrosion Cracking of Cold Worked Austenitic Stainless Steels in PWR Environment’, 13th International Conference on Environmental Degradation of Materials in Nuclear Power Systems, Whistler (Canada), 2007.

[[7]] F. Vaillant, L. Tribouilloy-Buisse, T. Couvant, ‘Stress Corrosion Cracking propagation of coldworked Austenitic Stainless Steels in PWR environment’, 14th International Conference on Environmental Degradation of Materials in Nuclear Power Systems, Virginia Beach (USA), 2009.

[[8]] C. Guerre et al., ‘SCC growth behavior of austenitic stainless steels in PWR primary water Conditions’, 12th International Conference on Environmental Degradation of Materials in Nuclear Power Systems, 2005.

[[9]] P. Andresen, P. Emigh, M. Morra, J. Hickling, ‘Effect of PWR primary water chemistry and deaerated water on SCC’, 12th International Conference Environmental Degradation of Materials in Nuclear Systems, 2005.

[[10]] K. Arioka, Y. Kaneshima, T. Yamada, T. Terachi, ‘Influence of boric acid, hydrogen concentration, and grain boundary carbide on IGSCC behaviors of 316 under PWR primary water’, 11th International Conference on Environmental Degradation of Materials in Nuclear Power Systems, Stevenson (USA), 2003.

[[11]] K. Arioka, T. Yamada, T. Teraci, G. Chiba, ‘Cold work and temperature dependence on crack growth behaviors of austenitic stainless steels in hydrogenated and oxygenated in high temperature water’, Fontevraud 6, 2006.

[[12]] T. Terachi, T. Yamada, T. Miyamoto, K. Arioka, ‘SCC growth behaviors of austenitic stainless steels in simulated PWR primary water’, Journal of Nuclear Materials, 426, p.59-70, 2012.

[[13]] M.L. Castano, M.S. Garcia, V.D. Diego, D. Gomez-Briceno, L. Francia, ‘Effects of hardening on the crack growth rate of austenitic stainless steels in primary PWR conditions’, Fontevraud V, 2002.

[[14]] T. Shoji, G. Li, J. Kwon, S. Matsushima, Z. Lu, ‘Quantification of yield strength effects on IGSCC in austenitic stainless steels in high temperature water’, 11th International Conference on Environmental Degradation of Materials in Nuclear Power System – Water Reactors. Stevenson (USA), 2003.

[[15]] D. Tice, N. Platts, K. Rigby, J. Stairmand, H. Fairbrother, ‘Environmentally assisted crack growth of col-worked type 304 stainless steel in PWR environments’, 12th International Conference on Environmental Degradation of Materials in Nuclear Power System – Water, 2005.

[[16]] D. Tice, JW. Stairmand, H.J. Fairbrother, A. Stock, ‘Crack growth testing of cold worked stainless steel in simulated PWR primary water environment to assess susceptibility to stress corrosion cracking’, 13th International Conference on Environmental Degradation of Materials in Nuclear Power Systems, Whistler (Canada), 2007.

[[17]] T. Couvant, E. Burger, C. Thaury, C. Rainasse, ‘Simulating the susceptibility to IGSCC of cold work 316 austenitic stainless steel exposed to primary water’, 19th International Conference on environmental degradation of materials in nuclear power systems – water reactors, Boston, USA, (2019).

Discover the Handbook of material ageing management for nuclear reactors

Discover the Handbook of material ageing management for nuclear reactors